Chocolate and Easter go hand-in-hand, meaning an Auckland chocolate shop has had to ramp up production to meet the growing demand.

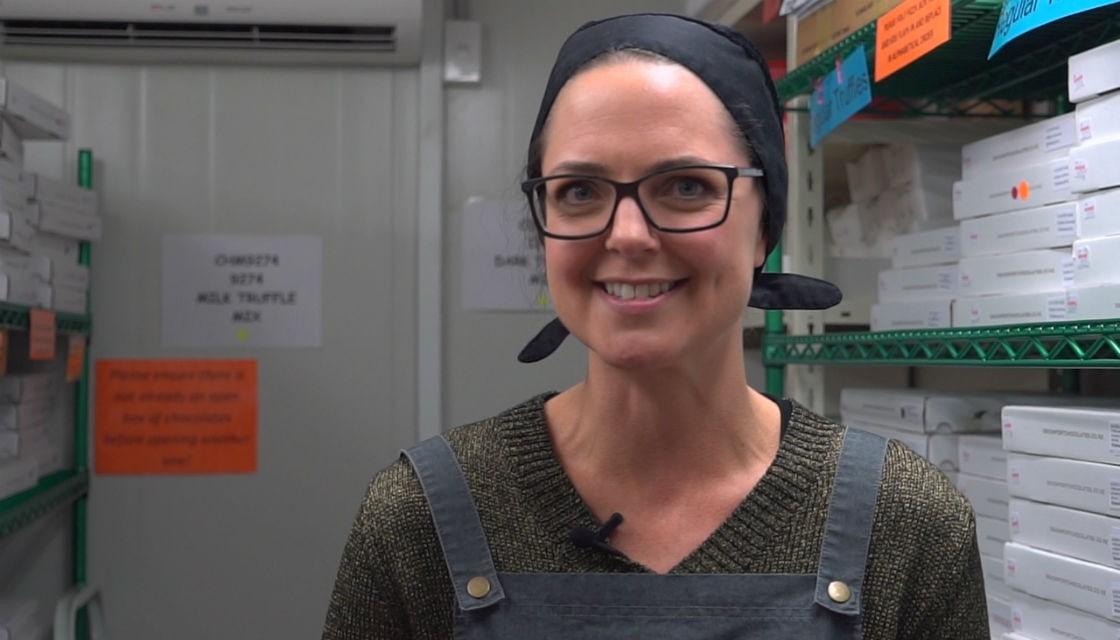

"Easter's getting bigger and bigger for us," says Caroline Everitt, retail general manager at Devonport Chocolates.

Everitt is also the owners' daughter, "because we're a family business".

The Everitts have run the chocolate shop since 1999 and, along with a factory shop in Devonport, have an outlet in Auckland City.

As expected, at this time of year it's Easter eggs that are most popular, including the Chesterfield eggs that are coloured in a satin finish to look like a galaxy.

Also popular are the handmade Easter bunnies - Mr Bunny and Steffie Bunny.

It takes an hour to make a single Mr Bunny, Everitt says. The attention to detail and care that goes into each bunny makes it so time consuming.

"First you hand-polish the mould, because chocolate is a reflective surface so, if the mould's dull, it will come out dull. Then you hand-pipe in the eyes and the nose and some details on the paws with white and milk chocolate.

"You then flood-fill the dark chocolate, into the mould, clip it together and then tip it out. Then, you wait for it to set and it [the bunny] pulls away from the mould. And, when you take the mould apart, you have a bunny."

She says buying quality chocolate, over quantity, is becoming more popular with families.

"Grandparents, especially, will come in and buy their grandchildren one special chocolate for Easter - it's become a tradition," she says.

Watch the video to see how Mr Bunny is made.

Newshub.